Request Demo

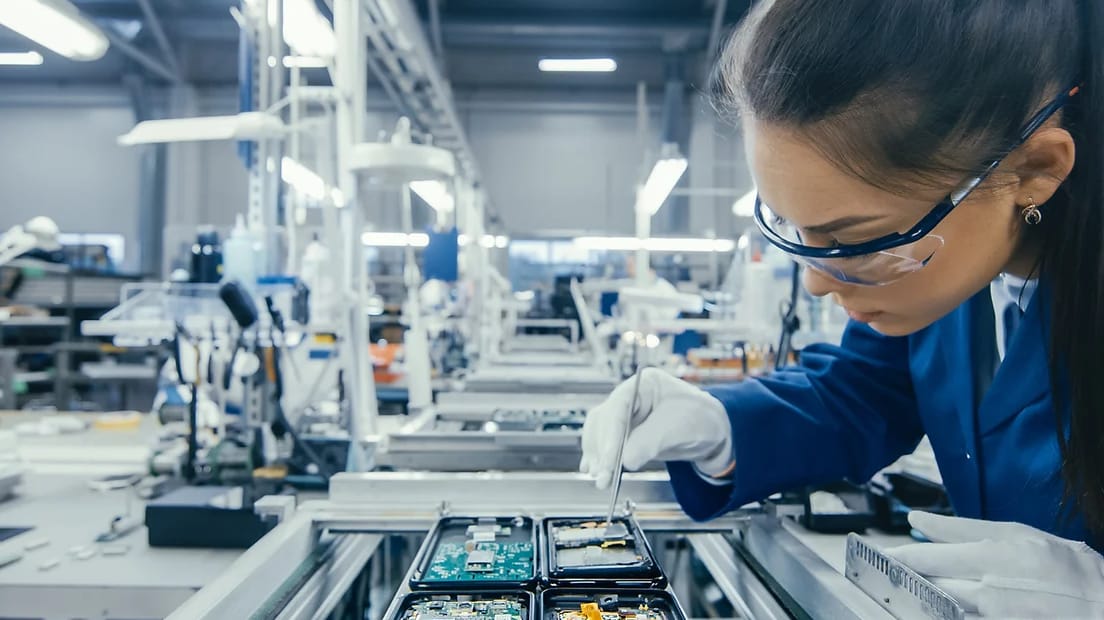

Prevent assembly errors as early as possible to decrease scrap rate

Improve your processes based on time and motion studies (coming soon!)

Automate operator guidance to optimize training and reliability

Adjust assembly processes based on end-of-line quality control

I can only recommend working with the team of ANTICIPATE. The solution offers great value in reducing manual errors. In addition, we were able to connect the system with our existing systems, such as pick-to-light and order management, without much effort.

Working with ANTICIPATE was characterized by a culture that puts the main focus on results and win-win outcomes at the center of all technical efforts at all times and across the board. I was impressed by the fast responsiveness and technical expertise in the collaboration.

We use AI-based video processing to track manual assembly activities. This will identify mistakes in real-time and help you to accelerate operator training.

Learn More

We use AI-based image processing to automate quality inspections of products and materials. This will relieve your staff from manual inspections.

Learn More

Kevin Denker

CEO, ANTICIPATE GmbH

Whether you have questions about features, pricing, trials or anything else, I am happy to hop on a call with you. Just send me an email or schedule time with me.

© 2024 ANTICIPATE GmbH. All rights reserved.